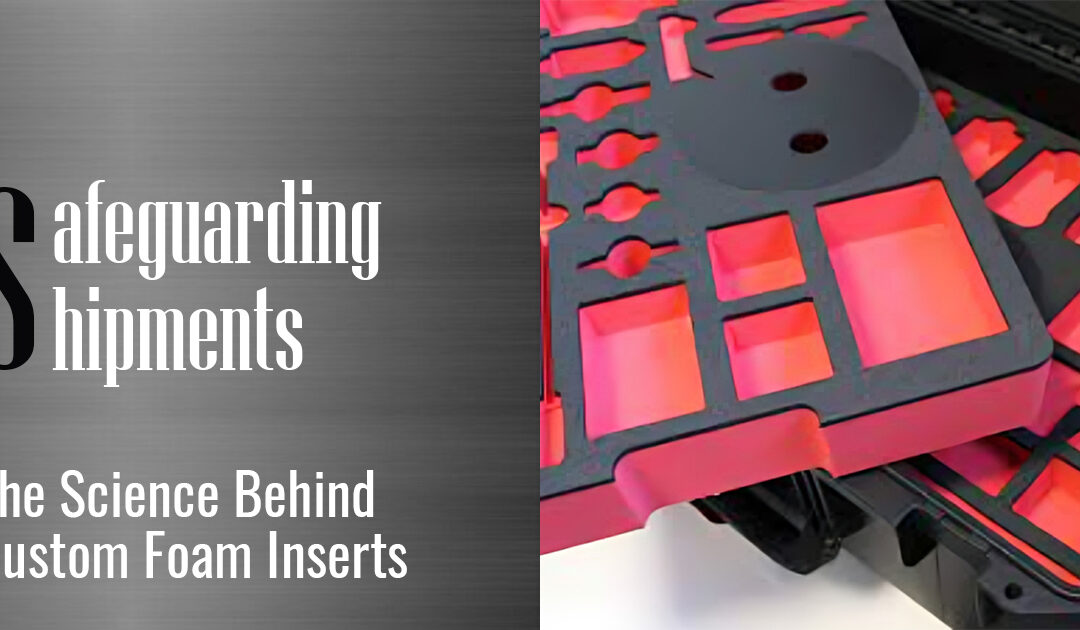

Shipping delicate items can be nerve-wracking. The fear of damage during transit often haunts both sellers and buyers. However, there’s a secret weapon in the packaging world that ensures safe travels for fragile goods – custom foam inserts. Let’s dive into the science behind these inserts and understand how they work to protect your items during shipping.

Understanding Custom Foam Inserts

What are Custom Foam Inserts?

Custom foam inserts are precisely shaped foam pieces designed to snugly fit inside packaging boxes. These inserts are tailored to cradle specific items, providing cushioning and support to prevent movement and absorb shocks during transportation.

The Science at Play

Material Composition:

Custom foam inserts are typically made from specialized foam materials like polyurethane foam or ethylene-vinyl acetate (EVA) foam. These materials possess unique properties that make them ideal for packaging:

• Shock Absorption: The foam’s cellular structure enables it to absorb and disperse external forces, reducing the impact on the packaged item.

• Flexibility: The foam can conform to the shape of the item, providing a custom-fit cushioning that minimizes movement.

Impact Protection:

During transit, packages can endure various types of impacts – drops, vibrations, or jostling. Custom foam inserts act as a protective barrier by absorbing the kinetic energy generated during these impacts, shielding the packaged item from damage.

Customization for Perfect Fit:

The key to the effectiveness of foam inserts lies in their customization. Each insert is meticulously designed and cut to precisely fit the contours and dimensions of the item it’s protecting. This tailored fit minimizes any empty spaces within the packaging, ensuring that the item remains snugly in place throughout the shipping process.

Reducing Vibrations:

Vibrations can be damaging, especially to sensitive items like electronics or glassware. Custom foam inserts dampen these vibrations, acting as shock absorbers and preventing excessive movement that could lead to breakage.

Advantages of Custom Foam Inserts

Optimal Protection:

The primary purpose of custom foam inserts is to provide superior protection. By cradling the item securely within the packaging, these inserts significantly reduce the risk of damage caused by impacts or shifts during shipping.

Versatility and Customization:

Custom foam inserts can be tailored to fit a wide range of products, from small electronic gadgets to intricate pieces of art. Their versatility allows for customization in terms of shape, density, and thickness to meet specific packaging requirements.

Cost-Effective Solution:

While initially an investment, custom foam inserts can ultimately save money by minimizing product damage and reducing the need for replacements or returns due to shipping-related issues.

Professional Presentation:

In addition to protection, custom foam inserts elevate the overall presentation of a package. A well-packaged item with custom inserts not only arrives safely but also showcases a level of professionalism that enhances customer satisfaction.

How Custom Foam Inserts Are Created

Design Phase:

The process begins with understanding the item’s dimensions and fragility. Using advanced design software, engineers create a digital model of the item and design the custom foam insert accordingly.

Material Selection:

Choosing the appropriate foam material is crucial. Factors like the item’s weight, fragility, and shipping conditions determine the type of foam used. Different densities and types of foam offer varying levels of protection.

Precision Cutting:

Once the design is finalized, the foam is cut using specialized cutting equipment such as water jet or CNC machines. These machines ensure precision and accuracy in cutting the foam to match the item’s contours.

Assembly and Insertion:

After cutting, the foam pieces are assembled and inserted into the packaging. Careful placement ensures that the item fits snugly within the foam insert, minimizing any movement.

Industries Benefiting from Custom Foam Inserts

Electronics and Technology: Items like laptops, smartphones, and delicate electronic components require precise protection during shipping. Custom foam inserts safeguard these items from impacts and vibrations.

Medical Equipment: Fragile medical devices and instruments need secure packaging to prevent damage. Custom foam inserts offer the necessary cushioning to keep these items intact.

Luxury Goods: High-end products like jewelry, collectibles, or luxury cosmetics demand premium packaging. Custom foam inserts provide a touch of luxury while ensuring safe delivery.

Automotive and Aerospace: Parts and components in these industries often require specialized packaging to withstand transportation stresses. Custom foam inserts offer tailored protection for such items.

The Future of Custom Foam Inserts

As technology advances and sustainability becomes a focal point, several trends are shaping the future of these inserts, revolutionizing their functionality, materials, and environmental impact.

1. Advanced Material Innovations

Smart Foam Materials:

Future developments may introduce smart foam materials embedded with sensors or responsive properties. These foams could detect changes in environmental conditions like temperature, humidity, or impact, providing real-time feedback on the status of the packaged items.

Biodegradable and Eco-Friendly Options:

With an increased emphasis on sustainability, the future of custom foam inserts may witness the rise of biodegradable and compostable foam materials. Innovations in bio-based materials could lead to eco-friendly foam options that maintain their protective properties while being environmentally responsible.

2. Enhanced Customization and Personalization

3D Printing Technology:

The advent of 3D printing in the manufacturing sector is likely to revolutionize the customization of foam inserts. This technology could enable on-demand production of highly tailored foam inserts, offering a level of customization and precision previously unseen.

AI-Driven Design Solutions:

Artificial intelligence (AI) and machine learning could play a significant role in designing custom foam inserts. AI algorithms analyzing data on product fragility, shipping conditions, and previous packaging designs could generate optimized foam insert designs for maximum protection.

3. Integration of Sustainable Practices

Recycled and Upcycled Materials:

The future of custom foam inserts might embrace the use of recycled or upcycled materials. Utilizing foam made from recycled plastics or repurposed materials could reduce waste and contribute to a circular economy approach in packaging.

Minimal Material Usage:

Advancements in design and engineering might lead to innovative foam insert designs that achieve maximum protection using minimal material. These designs would focus on efficiency, reducing material usage without compromising on safety.

4. Technological Integration for Tracking and Feedback

IoT Integration:

Integration of Internet of Things (IoT) technology within foam inserts could enable tracking and monitoring capabilities. Sensors embedded within the foam could provide data on the package’s location, handling conditions, and impact history, ensuring transparency throughout the shipping process.

Feedback Mechanisms:

Future foam inserts may incorporate feedback mechanisms that interact with shipping carriers or systems. These systems could alert carriers to handle packages with care or provide feedback to manufacturers based on the package’s journey.

5. Customization for Diverse Industries

Industry-Specific Designs:

As demand grows, custom foam inserts will likely evolve to cater to the specific needs of various industries. Tailored designs optimized for industries like healthcare, automotive, electronics, and aerospace will become more prevalent, addressing the unique packaging requirements of each sector.

The Impact on Packaging Practices

The evolution of custom foam inserts will undoubtedly influence packaging practices in multiple ways:

• Enhanced Protection: Advanced foam materials and designs will provide even greater protection for fragile items during shipping.

• Sustainability: The integration of eco-friendly materials aligns with the industry’s shift towards sustainable packaging solutions.

• Efficiency and Cost-Effectiveness: Optimized designs and materials may lead to more efficient production processes, reducing costs in the long run.

• Customer Experience: Improved packaging protection can enhance customer satisfaction, reducing the likelihood of product damage and returns.

Conclusion

Custom foam inserts are a game-changer in ensuring the safe shipping of delicate items. Their ability to conform to specific shapes, absorb shocks, and reduce vibrations makes them an indispensable tool in the packaging industry. By harnessing the science behind these inserts, businesses can not only protect their products but also enhance customer satisfaction and brand reputation.